Electroplating process waste water filter press

Basic Info

Model No.: BM/AGY-60/900-U

Product Description

TianGuan Electroplating process waste Water Filter press/ Advanced Dewatering adopts international advanced TPE membrane technology, so that ensure stable performance and long life-span, and widely used for various industries.Cake from membrane filter press can be secondarily squeezed under max 1.6MPa by water to realize the lowest cake residual moisture. In some wastewater treatment industries, the final cake can be used for landfill or burning directly.The membrane filter press can realize fully automatic operation with flexible devices, such as: belt conveyor, drip tray, cloth washing system, etc.

Electroplating process waste water filter press Advanced Dewatering Technical Data

Model Filter Area(m²) Filter Capacity(L) Plate size(mm) Plates Qty Cake Thickness(mm) X M/A Y 120/1250-U 120 1800 65×1250×1250 46 30 X M/A Y 125/1250-U 125 1875 65×1250×1250 48 30 X M/A Y 150/1250-U 150 2250 65×1250×1250 58 30 X M/A Y 160/1250-U 160 2400 65×1250×1250 62 30 X M/A Y 180/1250-U 180 2700 65×1250×1250 69 30 X M/A Y 200/1250-U 200 3000 65×1250×1250 77 30

Electroplating process waste water filter press Detail Photo

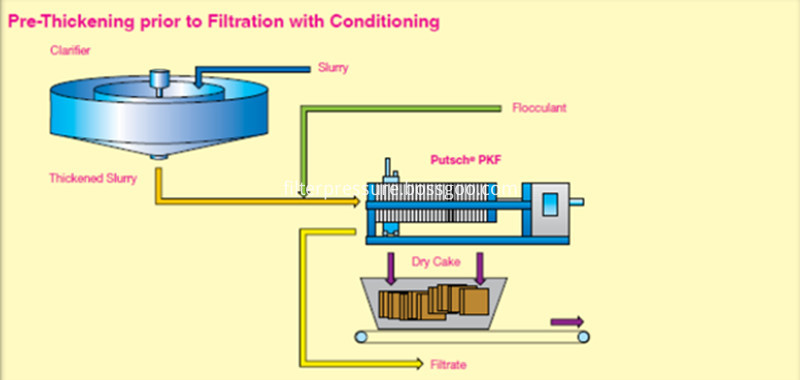

Electroplating process waste water filter press/ Advanced Dewatering Structure and operating principle

1. Filter press consist of frame ,filter plate ,pressing system(manual , mechanical or hydraulic ) and electric control cabinet .

2. Frame consists of base , push plate and girder and supports the pressing device and filter plates .

3. Filter plates are installed on girder between tail plate and push plate , with filter cloth sandwiched in them.

In operation , the pressing device(cylinder piston rod or screw ) drives the push plate to press the filter plates and filter cloth between push plate and tail plate . Filter chambers are formed between pressed filter plates and material get in to The filter chambers through the feeding port in tail plate . Solid particles are trapped in filter chambers form into cakes , while liquid is discharged out of the tail Plate . In similar manner ,to drying the press cakes , compressed air can be introduced through the washing port .

4. Plate and frame type filter-Press is the same as recessed plate filter press in structure ,except the filtering part that consists of one plate , one frame and filter cloth ,with filter chamber between plate and frame.

5. Liquid stream of filter press can be divided into exeternal stream and internal stream . exeternal streamrefers to that the filtrate is discharged directly from outlet port of filter plate; internal stream refers to that the filtrate from various filter plate is collected before being discharged out of the filtrate port .

After-sales Service of Elaspress high Pressure Filter Press/ Advanced Dewatering:

1.Documents supplied: Foundation/Circuit Diagram/Filter Cloth (or Filter Plate).

2.Site commissioning, installation and training service are valid.

3.Warranty: 13 months after B/L data.

Product Categories : Chemical Industry Filter Press > Chemical Industry Chamber Membrane Filter Press